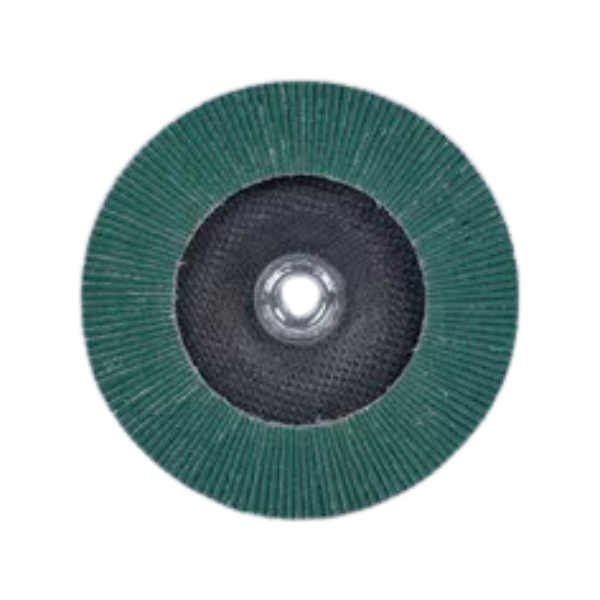

Flap Disc 577F

3M® Flap Disc 577F

Alumina and zirconia minerals cut faster than aluminum oxide on all types of metal

Flaps combine roughing and blending in one step to save time

Durable YF-weight polyester-reinforced flaps provide longer life in high-pressure applications such as sharp-edge work and beveling

The 3M® 577F Flap Disc is designed to tackle the toughest high-pressure applications in the metalworking industry, delivering a smooth finish in a single step.

Our flap disc features aluminum zirconia for fast cuts on durable, polyester-reinforced sheets, providing extra cutting power and extended service life in demanding tasks like weld removal, edge work, and beveling.

Engineered for demanding polishing applications

The overlapping layers of the 3M® 577F Flap Disc, ideal for intensive polishing tasks where the final touch matters, wear down continuously to expose fresh abrasive minerals. This ensures fast and consistent cutting while the cushion of the flaps creates a uniform finish. Flap discs often deliver a finish that is one grade finer than discs of the same grit, reducing process steps.

A polishing aid reduces the working temperature in processes involving heat-sensitive alloys such as stainless steel, nickel alloys, and titanium. Flap discs are used with right-angle grinders. Giant flap discs, which share the same diameter as standard discs but have wider flaps, offer extra-thick layers and 25% more abrasive material than standard discs. This results in more aggressive cutting and longer disc life.

Superior performance and cost efficiency

Flap discs are three-dimensional polishing tools with overlapping layers of abrasive-coated flaps reinforced with fibers, fanning out from a central hub. As the flaps wear down, fresh minerals are exposed for consistent, fast cuts.

Flap discs are a one-step alternative to bonded wheels and fiber discs, performing both grinding and finishing in a single stage. This makes them a time- and cost-saving solution for many typical applications. Under normal conditions, flap discs provide a finish one grade finer than a fiber disc of the same grit. Additionally, their layered structure allows for more abrasive material on the cutting surface, leading to significantly longer life than traditional discs.

Versatile and ergonomic

Flap discs are flexible enough to easily follow curves and contours, reducing gouging and enhancing operator comfort. They are ideal for a wide range of applications, including:

- Polishing small welds

- Deburring

- Rust removal

- Edge polishing

- Smoothing weld seams

There are no reviews yet.