LD6025

Quick Overview

The Labelmoto LD6025 electric label dispenser dispenses short-length and tiny barcode labels and die-cut parts made from paper, polyester, vinyl, acetate, foam, foil, and other materials. The LD6025 has a photosensor, which ensures that the unit peels, dispenses, and advances accurately and consistently. The liner scrap is automatically rewound for a clean working environment. No tools are required to adjust the dispenser for different label sizes. It also has an adjustable strip plate for hard-to-release labels.

Descripción

The Labelmoto LD6025 electric label dispenser dispenses short-length and tiny barcode labels and die-cut parts made from paper, polyester, vinyl, acetate, foam, foil, and other materials. The LD6025 has a photosensor, which ensures that the unit peels, dispenses, and advances accurately and consistently. The liner scrap is automatically rewound for a clean working environment. No tools are required to adjust the dispenser for different label sizes. It also has an adjustable strip plate for hard-to-release labels. The dispenser has a high torque motor to handle the weight of large-diameter label rolls, with a maximum outside roll diameter of 12″/305 mm. The dispenser housing is made from anodized aluminum for durability. The LD6025 label dispenser operates on 100/120 VDC at 50/60 Hz. This label dispenser is made in the U.S. It is suitable for industrial uses such as manufacturing, assembly, and packaging.

FEATURES

- Replacement for LD5000

- Electric label dispenser for short length and tiny barcode labels made of paper, vinyl, acetate,

- polyester, foam, foil, and other materials

- NEW built-in hanging capability for use with workbenches & LDHANGER16

- Accepts 1″/25 mm and 3″/76 mm roll core sizes; 12″/305 mm maximum outside roll diameter

- For labels 0.25 to 4.5″ (6 to 114 mm) wide and 0.125 to 6″ (3 to 152 mm) long

- Feed speed is 1.6″/41 mm per second

- High torque motor for large-diameter label rolls

Label dispensers and label applicators help remove a label from its liner or backing paper. They are used in manufacturing, bulk mailing, packaging, and the food and beverage industry. Manual label applicators and multi-roll label dispensers are useful for small jobs. The operator pulls the liner or backing paper around a plate or a bar, peeling the label away from the liner. High-speed electric label dispensers are often used in industrial settings. When the operator removes a label, a sensor detects its absence and switches the motor to advance the label roll. The label is pulled over a strip plate, which separates the label and its liner. Electric label dispensers use either a photosensor or a limit switch as a sensor. Specialized label dispensers of both manual and electric types are designed for labels of unusual size or material such as bottle and jar labels, die-cut parts, and hang tabs.

What’s in the Box?

- LD6025 high-speed electric label dispenser

- Power cord

- Instructions

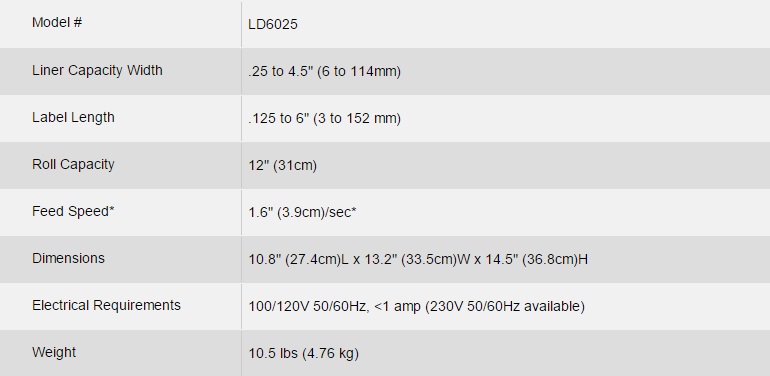

Product Specifications